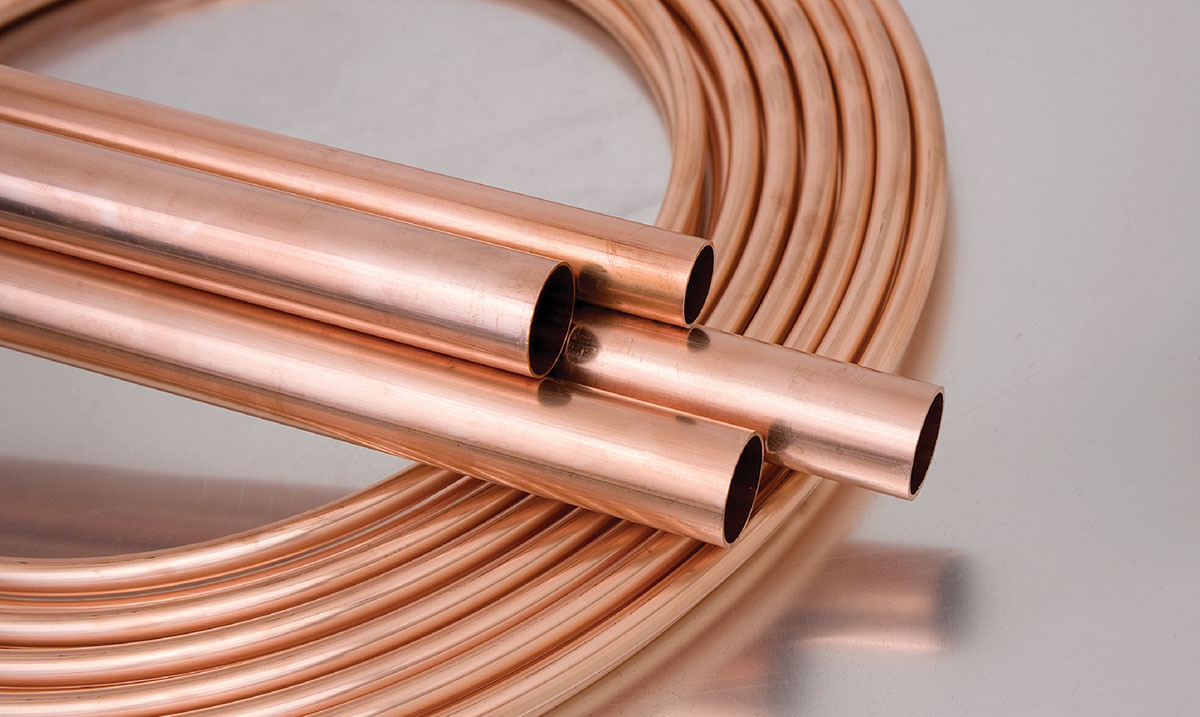

Enhancing Your Cooking Area with Premium Copper Products: Tips and Ideal Practices

The Relevance of Quality in the Manufacturing of Copper Products

The importance of quality in the manufacturing of copper products extends much beyond simple compliance; it is important to optimizing efficiency across various markets. As we explore the complex nature of top quality, the question arises: exactly how can suppliers balance these obstacles to accomplish quality?

Influence On Item Performance

The top quality of copper products plays a vital role in identifying their general efficiency in numerous applications. Premium copper exhibits exceptional electric conductivity, thermal conductivity, and corrosion resistance, which are necessary qualities for sectors such as electronics, building, and vehicle.

Furthermore, the mechanical properties of copper, including ductility and tensile strength, considerably affect its performance in producing processes. Copper items that fulfill rigorous high quality requirements can hold up against substantial stress without deforming, thus enhancing toughness and lowering the chance of failure sought after settings.

Additionally, the surface area finish of copper items influences their efficiency. A smooth, well-treated surface area can avoid oxidation and other forms of deterioration, inevitably lengthening the life of the part. In summary, the quality of copper products directly influences their performance, dependability, and durability across different markets, making it essential for manufacturers to comply with extensive quality assurance measures throughout the manufacturing procedure.

Expense Implications of Poor Top Quality

Spending in top notch copper products is essential, as the cost implications mediocre can be substantial for makers and end-users alike. Poor quality copper can cause increased failing prices, leading to costly repair services and substitutes. Producers might deal with considerable downtime as defective items demand remembers or rework, interrupting production timetables and affecting general efficiency.

From an end-user point of view, the ramifications are just as serious. Poor-quality copper can cause inefficiencies and raised operational costs, as tools may call for even more frequent upkeep. Eventually, the initial financial savings acquired from picking lower-quality copper products can be outweighed by these long-lasting costs, making the quest of quality not simply a matter of efficiency, yet a crucial economic factor to consider in the manufacturing market.

Safety and Compliance Requirements

Ensuring safety and conformity standards in the production of copper products is vital to preserving operational stability and safeguarding both staff members and customers. The production process have to stick to strict laws set forth by organizations such as the Occupational Security and Health Management (OSHA) and the Environmental Protection Agency (EPA) These policies lay out crucial security methods, including appropriate handling of raw products and waste administration, making certain a safe workplace.

Additionally, conformity with sector visit this page criteria such as ASTM International and ISO accreditation is essential. These companies give standards that assist manufacturers execute best techniques in quality assurance and precaution. Regular audits and inspections need to be performed to guarantee adherence to these criteria, as non-compliance can bring about hazardous problems and prospective lawful ramifications.

Customer Count On and Satisfaction

Trust fund and satisfaction amongst clients play a pivotal function in the success of copper product producers (Copper Products). Top quality copper products not just fulfill rigorous industry standards yet also accomplish customer assumptions, cultivating loyalty and repeat company. When consumers are certain in the high quality of the products they buy, they are most likely to establish a long-lasting relationship with the maker, which can cause recommendations and favorable word-of-mouth

To build this depend on, producers should focus on top quality control throughout the production procedure, ensuring that each copper product meets or surpasses specs. Transparency in producing techniques, paired with commitment to consumer solution, reinforces the understanding of dependability. In addition, timely shipment and responsiveness to consumer questions considerably improve fulfillment degrees.

Consumer responses ought to be proactively looked for and integrated into product advancement cycles to continuously boost offerings. Involving consumers in discussion about their preferences and demands grows a feeling of collaboration, additional solidifying their rely on the manufacturer. Ultimately, a credibility for quality and customer-centric techniques identifies effective copper product suppliers in an affordable market, preparing for enduring client connections.

Long-term Company Success

A maker's dedication to top quality is important to accomplishing long-term published here organization success in the affordable copper products market. High-quality products foster consumer loyalty, ensuring repeat business and positive referrals that drive growth. In a sector where dependability and performance are extremely important, business that focus on high quality over cost-cutting procedures are most likely to stand apart.

In addition, consistent top quality reduces the occurrence of defects and revamp, resulting in lower functional expenses and increased efficiency. This structured production process allows manufacturers to designate resources effectively, permitting for investments in technology and modern technology. Services that adjust to invest and market adjustments in high quality improvements are much better placed to fulfill developing consumer needs.

In addition, maintaining rigid top quality standards improves a firm's reputation, attracting brand-new customers and possible collaborations. A durable track record for high quality can act as a differentiator in jampacked markets, opening up doors to financially rewarding agreements and collaborations.

Ultimately, an unfaltering dedication to top quality not why not try this out just makes certain compliance with industry regulations but likewise grows a sustainable business design. By installing high quality into every element of the production process, companies can protect their location as leaders in the copper items sector, leading the way for withstanding success.

Verdict

In conclusion, the importance of top quality in copper item manufacturing is vital. As sectors progressively rely on copper for critical applications, maintaining extensive high quality control is necessary to safeguard a competitive benefit and promote a reputable market existence.

The value of top quality in the manufacturing of copper products expands far beyond simple compliance; it is indispensable to optimizing efficiency across numerous industries. In summary, the high quality of copper products straight affects their performance, integrity, and longevity across various markets, making it crucial for suppliers to stick to rigorous high quality control procedures throughout the production procedure.

A maker's commitment to quality is integral to attaining long-lasting service success in the affordable copper items market.